An architect recently told me about his experience trying to remodel a building he had designed 10 years earlier. The owner, satisfied with the building’s performance, now wanted to use the same specifications for an addition. To the architect’s dismay, however, half of the building products used just a decade earlier were no longer available. Other products were still available, but were no longer the best or most economical materials. This story illustrates the constant change in the building products industry. Driven by new technology, intense competition, and changing market conditions, manufacturers are constantly developing and improving products. To celebrate this parade of progress, we are highlighting a handful of the best new building products of the past year or so. I have selected products that address a cross-section of contemporary marketing concerns. Some represent trends that will shape the industry’s future. Others are useful reminders of marketing fundamentals. All, I hope, will stimulate you to take a fresh look at your own products and markets.

Old wine, new bottles

Product, price, place, packaging, and promotion are the five P’s of marketing. Of these, packaging is probably the most overlooked by the building products industry.

Recent innovations in concrete admixtures, however, demonstrate the marketing importance of packaging. Several companies have introduced packages that dissolve when tossed into concrete mixers. These portion-controlled units are easier to use because they do not require opening, measuring, or pouring. Some manufacturers even claim that their products disperse more rapidly and uniformly because they release materials in the center of the mixer rather than on top of the batch materials. Playing upon environmental concerns, manufacturers also advertise that the new packaging reduces waste-disposal costs.

Mix-Ready bags by Davis Colors, containing powdered pigments for integrally colored concrete, are typical of this new packaging. The bags are made of special papers and adhesives that get soggy and disintegrate without affecting the concrete mix. Ready mix producers like the packaging because it is cleaner to handle and eliminates the colored dust created when pouring pigments.

Attractive graphics on the bags reinforce product identity and carry Davis Colors’ promotional campaign right into the customer’s shop. The bags differentiate the product from other dry pigments, and reduce the competitive threat from liquid pigment systems that also offer clean handling.

Through the wired glass

The pervasive influence of building codes on the construction industry spurs product development and creates marketing opportunities. This was apparent when the Americans with Disabilities Act became law recently, and also several years ago when the ACI530.1 masonry engineering code requirements were issued. But sometimes marketing opportunities go untapped for years before they are exploited.

Codes governing glass doors are a good example. These codes require glass in doors to be safety-glazed so it will not shatter when broken. They also require glass in fire doors to be fire-resistant. But, until recently, no product on the market satisfied both codes. For decades, firereinforced glass, considered unattractive by many designers, was used because it was the only practical fireresistant glass on the market. But it did not meet the safety-glazing requirement.

Several recently introduced products are both safety-glazed and fireresistant. Among them are a Japanese ceramic and a European composite panel filled with a clear fire-resistant gel, but they are expensive. Also, the ceramic lacks the clarity of conventional glass, and the composite is thick and heavy.

Georgian Colored Wire Laminated Glass from FDI Glass Corp. is one of the latest attempts to satisfy both codes. Instead of casting the wire mesh into the body of the glass, FDI ’s patented process laminates the wire in a clear resin sandwiched between two lights of glass. The wire reinforces the glass so that it can withstand fire testing, and the resin laminate restrains broken pieces of glass. The product is thin enough to fit conventional glazing frames, and is priced well below the other products that comply with both codes. FDI also offers a choice of wire colors, transforming an aesthetic liability into a design feature.

Ignoring the rules

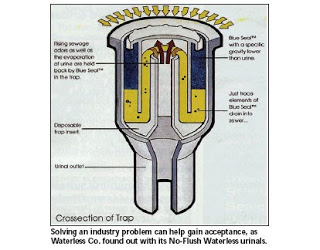

Almost every rule of building technology I learned in school is now obsolete. I was taught that to prevent sewer gasses from entering a building, a water trap must be connected to vent pipe. The most recent innovation to ignore this rule is the No-Flush Waterless urinal from Waterless Co. These urinals do not require water for flushing. Instead, an oil-based liquid seals the S-trap against sewer gasses and odors.

The waterless urinals pay for themselves by reducing a building’s water bill. They also reduce the effluent flow into the sewer system, making them attractive to communities with inadequate sewage treatment capacity. But most of the sales will be for the retrofit or renovation of existing buildings, the fastest growing segment of the construction industry.

Waterless urinals are not a new invention; over 1 million units are already in use in Europe. However, the U.S. construction industry is notoriously slow to accept new technology. To help overcome the anticipated resistance to its product, Waterless Co. timed its North American introduction to coincide with a prolonged drought in Southern California that pressured the entire industry to consider alternatives.

A two-for-one deal

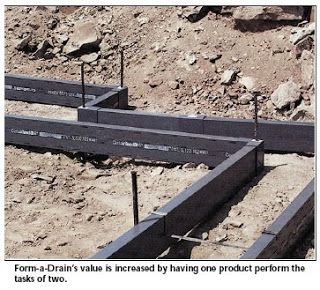

In the past year, there has been a flurry of marketing activity for new plastic products, including roof shingles, light fixtures, and even “lumber.” Form-a-Drain, from Certainteed Pipe & Plastics Group, is an example of the growing use of plastics in construction. But its marketability really comes from the fact that it does a job that previously required two separate products.

Form-a-Drain, a rectangular plastic extrusion with a slotted side wall, is designed to take the place of form board for foundation footings. It is left in place when the foundation is back-filled, replacing perforated pipe normally used for drainage. And it costs less than perforated piping and conventional form boards used together.

Capitalizing on volatile timber prices, part of Certainteed’s marketing strategy has been to emphasize Forma- Drain’s stable prices. In addition, the company plays up the fact that unlike wood, Form-a-Drain comes in true dimensions and does not warp, rot, or attract termites. The product also has some recycled content, making it attractive to those in the industry who prefer to use recycled products in their buildings.

Have a question you'd like us to answer?

Send an email to michaelchusid@chusid.com

By Michael Chusid

Originally published in Construction Marketing Today, Copyright © 1993

Old wine, new bottles

Product, price, place, packaging, and promotion are the five P’s of marketing. Of these, packaging is probably the most overlooked by the building products industry.

Recent innovations in concrete admixtures, however, demonstrate the marketing importance of packaging. Several companies have introduced packages that dissolve when tossed into concrete mixers. These portion-controlled units are easier to use because they do not require opening, measuring, or pouring. Some manufacturers even claim that their products disperse more rapidly and uniformly because they release materials in the center of the mixer rather than on top of the batch materials. Playing upon environmental concerns, manufacturers also advertise that the new packaging reduces waste-disposal costs.

Mix-Ready bags by Davis Colors, containing powdered pigments for integrally colored concrete, are typical of this new packaging. The bags are made of special papers and adhesives that get soggy and disintegrate without affecting the concrete mix. Ready mix producers like the packaging because it is cleaner to handle and eliminates the colored dust created when pouring pigments.

Attractive graphics on the bags reinforce product identity and carry Davis Colors’ promotional campaign right into the customer’s shop. The bags differentiate the product from other dry pigments, and reduce the competitive threat from liquid pigment systems that also offer clean handling.

Through the wired glass

The pervasive influence of building codes on the construction industry spurs product development and creates marketing opportunities. This was apparent when the Americans with Disabilities Act became law recently, and also several years ago when the ACI530.1 masonry engineering code requirements were issued. But sometimes marketing opportunities go untapped for years before they are exploited.

Codes governing glass doors are a good example. These codes require glass in doors to be safety-glazed so it will not shatter when broken. They also require glass in fire doors to be fire-resistant. But, until recently, no product on the market satisfied both codes. For decades, firereinforced glass, considered unattractive by many designers, was used because it was the only practical fireresistant glass on the market. But it did not meet the safety-glazing requirement.

Several recently introduced products are both safety-glazed and fireresistant. Among them are a Japanese ceramic and a European composite panel filled with a clear fire-resistant gel, but they are expensive. Also, the ceramic lacks the clarity of conventional glass, and the composite is thick and heavy.

Georgian Colored Wire Laminated Glass from FDI Glass Corp. is one of the latest attempts to satisfy both codes. Instead of casting the wire mesh into the body of the glass, FDI ’s patented process laminates the wire in a clear resin sandwiched between two lights of glass. The wire reinforces the glass so that it can withstand fire testing, and the resin laminate restrains broken pieces of glass. The product is thin enough to fit conventional glazing frames, and is priced well below the other products that comply with both codes. FDI also offers a choice of wire colors, transforming an aesthetic liability into a design feature.

Ignoring the rules

Almost every rule of building technology I learned in school is now obsolete. I was taught that to prevent sewer gasses from entering a building, a water trap must be connected to vent pipe. The most recent innovation to ignore this rule is the No-Flush Waterless urinal from Waterless Co. These urinals do not require water for flushing. Instead, an oil-based liquid seals the S-trap against sewer gasses and odors.

The waterless urinals pay for themselves by reducing a building’s water bill. They also reduce the effluent flow into the sewer system, making them attractive to communities with inadequate sewage treatment capacity. But most of the sales will be for the retrofit or renovation of existing buildings, the fastest growing segment of the construction industry.

Waterless urinals are not a new invention; over 1 million units are already in use in Europe. However, the U.S. construction industry is notoriously slow to accept new technology. To help overcome the anticipated resistance to its product, Waterless Co. timed its North American introduction to coincide with a prolonged drought in Southern California that pressured the entire industry to consider alternatives.

A two-for-one deal

In the past year, there has been a flurry of marketing activity for new plastic products, including roof shingles, light fixtures, and even “lumber.” Form-a-Drain, from Certainteed Pipe & Plastics Group, is an example of the growing use of plastics in construction. But its marketability really comes from the fact that it does a job that previously required two separate products.

Form-a-Drain, a rectangular plastic extrusion with a slotted side wall, is designed to take the place of form board for foundation footings. It is left in place when the foundation is back-filled, replacing perforated pipe normally used for drainage. And it costs less than perforated piping and conventional form boards used together.

Capitalizing on volatile timber prices, part of Certainteed’s marketing strategy has been to emphasize Forma- Drain’s stable prices. In addition, the company plays up the fact that unlike wood, Form-a-Drain comes in true dimensions and does not warp, rot, or attract termites. The product also has some recycled content, making it attractive to those in the industry who prefer to use recycled products in their buildings.

Have a question you'd like us to answer?

Send an email to michaelchusid@chusid.com

By Michael Chusid

Originally published in Construction Marketing Today, Copyright © 1993